This is Page 4 of 4 from the Ranger Boats Product Knowledge Tour (December 6, 2004) - Building Quality Bass Boats pages. Continuing on, we'll look at the finishing of the boat, along with the support products and specialties that make the difference between a good boat and a great boat.

Building a Quality Bass Boat Pages

Finishing the Boat

Support / Specialty Areas

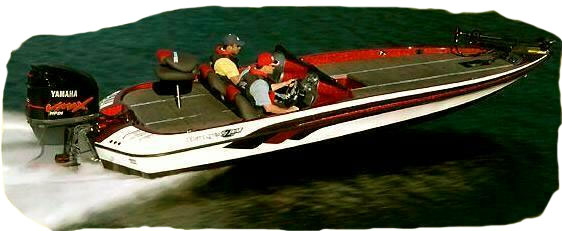

Every boat must pass the ‘tank test’ before it is approved for release to its new proud owner. Here’s a wicked new Z21 with (my favorite) a Yamaha VMax HPDI 250 hung on the back being prepared for the ‘test.’ The Ranger tech will lower this beautiful new Z into the water to test fittings for leaks, check proper operation of the bilge and livewells pumps, and all the other parts that make up a great fishing machine. To the right of the tank, techs are rigging up a Team boat – this one from Team Snickers. There’s a corner of the shop just for Team boat wraps.

In the tank now, the rear compartments open, the tech is letting water into the boat to test the pumps – bilge #2 in this photo. The tech tracks each test as she goes through the list. This boat won’t be released from the factory until she has given every single item a passing grade.

If she finds anything questionable, back to the appropriate area the boat goes. She has the power, no doubt about it. She’s like ‘Inspector #4’ that you see in items you buy. If she won’t release the boat, it won’t leave the factory. I’m a huge fan of checklists when it comes to finishing a job and guaranteeing you’ve done it right. Double-checking even.

When all the building, rigging and testing is done – What you end up with –

A LEAN MEAN FISHING MACHINE!!

Other important production areas include the sewing room where all the seat and boat covers are made. Employees who’ve been sewing these materials for years run industrial sewing machines. Ranger uses top quality UV-treated threads designed for the marine environment.

Boat covers are sewn to order based on the motor, electric motor, windshields and other components the cover has to fit over. The new deluxe ratcheted cover uses two ratchets in the back to create an incredibly tight seal that greatly improve aerodynamics for trailering. It will save you gas money.

One of my favorites –the computerized laser-cutting machines. Ranger uses these high-tech machines to cut backing for seats, seat material, carpeting, and so much more – just about everything except pultruded fiberglass and the boats. You just lay the material out on the table, select the pattern, stand back and start her up. The arm at the far end moves across the material very fast, silently cutting exact fitting shapes every time. It doesn’t look like it’s doing anything until you pick up the material and the pieces fall out. Consistency is guaranteed.

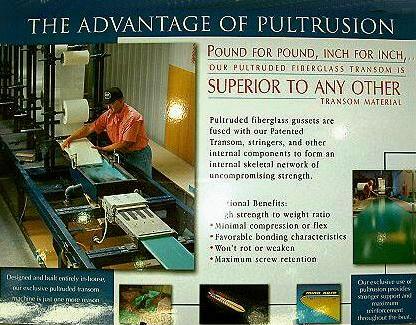

Pultruded fiberglass is a patented Ranger Boats exclusive. No other boat builder has it. Pultrusion is a high tech process that takes 40 to 70 sheets of various fiberglass types from the big rack and runs it under pressure through a heated dye-resin bath. The result is an incredibly strong substance that is 75% fiberglass and only 25% resin. Pultruded fiberglass is so dense, they need to cut it with a 55,000-psi water saw. Blades build up heat too fast. You end up with excellent screw retention too. Just predrill the holes.

Pultruded fiberglass won’t rot or weaken ever. It’s like having an armored boat – all part of Ranger’s Zone-Tempered Fiberglass Layup that makes for a top quality boat.

Ranger has built RangerTrail trailers since 1978 to custom fit every Ranger Boat. Ranger puts as much innovation into making these quality, long lasting trailers as they do their boats.

Summer of 2004 saw a complete retooling of the trailer shop. Thanks to the new exclusive Road Armour coating, the ceramic heat booths are gone, so Charley and company now have air conditioning for the first time. Makes for a friendlier work environment, but you want to hear about improvements in the trailers. There are many this year.

Ranger Boats recently built their 100,000th trailer. They’ve gotten pretty good at it. Every RangerTrail trailer starts as

open channel and flat steel stock. Open channel frames allow the entire trailer to be coated and doesn’t leave enclosed areas for moisture to be trapped. The metal is cut, formed and welded in Ranger-made jigs. Some frames to be used in saltwater are sent out to be hot-dip galvanized. The rest are primed and now coated with the incredibly tough Road Armour coating that is practically impervious to road damage.

Besides the tough new coating, Ranger added LED lights to the trailer that have a lifetime warranty from their manufacturer. Along with the stronger, higher fiberglass content fenders created by the CCBM process, you should get much more enjoyment out of your trailer with less maintenances.

They’ve switched from springs to torsion bars in the axles – shown here. This improves the trailer ride and simplifies service, but for dual axle trailers it’s imperative that you make sure the trailer is level so you don’t put undo pressure on the front or rear axle. I really like the new reinforced footstep added to the center of dual axles (shown center previous box photo). Very convenient. Ranger has also improved the brake parts for longer lasting, cooler operation and simpler maintenance. Ranger’s Exclusive C.O.O.L. hubs are new too – the cap now screws into the hub – there’s no spring to push the cap in and out. The lube oil doesn’t completely fill the hub now.

The RangerTrail trailer tongue has changed dramatically. There’s a new and improved brake assembly, a new, much nicer winch, and a new center mounted flip-up dolly wheel that should stabilize trailer maneuvering while being completely out of the way when locked up into the trailer frame why you trailer your fishing machine to the lake.

And Charley Smith, long-time trailer shop manager says he’s confident he’s finally found the best material for the bow eye roller. After testing thoroughly, Charley says the new bow roller is strong yet doesn’t look like it will scuff up the boat like many other rollers do. Of course, maybe some of us ram the boat up onto the trailer a little too hard also…

Ranger Boats – a great example of a quality company building a quality product. I personally need to have confidence in a product to use it over the long haul, and especially before I can recommend it to other anglers and friends I know. There are products I have confidence in and then there are products I believe in. Because of their philosophy and constant drive to improve, I have real faith in Ranger Boats.

I won’t tell you to buy a Ranger Boat, but I hope you see the value in their products and also end up a more educated consumer when you go to look for that next fishing boat.

Some of the basic boat building is similar to how many boat brands are built. There will just be differences in materials and specific processes, some of which have been spelled out on these pages.

As far as Ranger Boats, their number one concern according to 19-year employee Hugh Dewey, is to build “the safest and best fishing boat that looks good on the water.” I get the definite impression that all of the over 700 Ranger employees work with that goal in mind. Ranger Boats has a large percentage of employees who have 15 to 35 years of experience.

Now, the pictures many of you have been asking about – the exciting new Ranger Z-Comanche Series boats are covered with the pictures and information I have on them so far.